BUSINESS

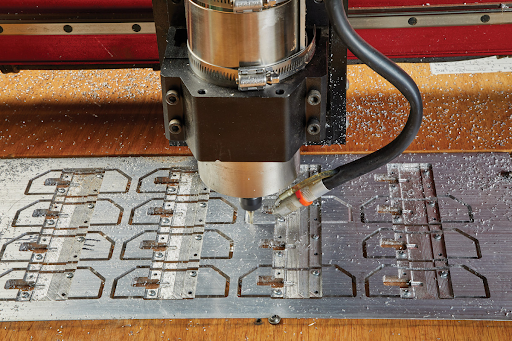

Can You CNC Router Brass

Brass is popular in various industries due to its aesthetic appeal, excellent machinability, and favorable mechanical properties. It is widely used for decorative elements, musical instruments, fittings, and more. With the advent of CNC (Computer Numerical Control) technology, manufacturing processes for brass have evolved, providing more precision, speed, and versatility. However, one common question remains: Can you CNC router brass effectively?

This article explores the feasibility of using CNC routers to machine brass, considering their properties, benefits, challenges, and best practices to follow for optimal results.

What Is Brass?

Brass is an alloy majorly composed of zinc and copper, varying proportions depending on the desired properties and applications. The zinc in the alloy increases its strength and hardness and enhances its resistance to corrosion and wear. Brass is known for its golden, lustrous appearance, making it a favored choice for decorative applications. It also has good thermal and electrical conductivity. This makes it perfect for electrical components.

Brass can exhibit different characteristics depending on the zinc content and the inclusion of other elements like lead, aluminum, or tin. Examples are improved machinability or enhanced corrosion resistance. This versatility makes brass a sought-after material for various industries, including construction, musical instrument manufacturing, plumbing, and electrical applications.

Can You CNC Router Brass?

Yes, you can use a CNC router to machine brass. However, it’s important to understand the complexities and take necessary precautions. Brass is a soft metal compared to other alloys like steel or titanium, which makes it more machinable. However, its density and hardness still pose unique challenges for CNC routers, traditionally designed to work with softer materials like wood, plastic, and composites. With the right modifications and machining strategies, a CNC metal router can successfully cut, shape, and engrave brass, allowing for complex designs and high-quality finishes.

One of the primary considerations when using a CNC router on brass is the rigidity and stability of the machine. CNC routers must be strong enough to withstand the forces generated during metal machining. If the machine is sufficiently flexible, the vibrations and tool deflection can result in better-quality cuts, reduced precision, and even damage to the machine or workpiece. Therefore, it’s essential to ensure that the CNC router is sturdy, has a stable work table, and uses a high-torque spindle to handle the increased forces exerted by the brass.

Selecting the right cutting tools is also crucial. For machining brass with a CNC router, carbide or solid carbide tools are recommended due to their hardness and resistance to wear. These tools can maintain their cutting edge longer than high-speed steel (HSS) tools and withstand the heat generated during machining. Sharpness is a key factor when working with brass since dull tools can cause burr formation, rough surfaces, and increased friction, which leads to overheating and tool failure. Additionally, smaller tools should be avoided, as they can easily snap under the higher cutting forces involved.

The machining parameters, such as spindle speed and feed rate, must be carefully adjusted when routing brass. Running the CNC router at too high a speed can cause the tool to overheat, while too low a speed can result in poor chip evacuation and a rough finish. A moderate spindle speed combined with a relatively high feed rate is ideal for brass machining. This balance ensures that the cutting tool stays cool, reduces the risk of chatter, and improves the overall surface finish. Additionally, using a toolpath strategy such as climb milling is beneficial, as it helps minimize tool deflection and enhances accuracy.

Another factor to consider is the use of coolant or lubrication. Although brass doesn’t require as much cooling as harder metals, applying a lubricant or coolant can help reduce friction and prevent overheating. This step is particularly useful when machining for extended periods or when performing deep cuts, as it prolongs tool life and maintains the quality of the machined surface. Mist cooling or a small amount of cutting oil applied directly to the toolpath can make a significant difference in achieving a smooth, precise cut.

Finally, optimizing the toolpath strategy is essential for successful CNC routing of brass. Depth of cut, step-over, and tool engagement must be controlled to maintain stability and avoid tool breakage. Shallow passes with smaller depth cuts help prevent the tool from binding and reduce the chances of deflection. Moreover, using a spiral toolpath or a combination of roughing and finishing toolpaths can ensure that material removal is efficient and that the final product has a clean, smooth finish.

Applications of CNC Router Brass

Here are some of the key applications of CNC routing for brass:

Decorative and Architectural Elements

Brass has a natural, attractive finish that can be polished to a bright, golden luster, making it a popular choice for decorative items. CNC routers machine complex patterns, engravings, and 3D reliefs on brass panels or sheets for home décor, furniture accents, custom signage, and architectural details. These elements add elegance and style to traditional and contemporary designs, making brass a sought-after material for artistic applications.

Jewelry and Fashion Accessories

The precision of CNC routing allows for creation of detailed jewelry pieces such as pendants, rings, bracelets, and brooches. Brass’s ease of machinability means that fine cuts, delicate designs, and personalized engravings can be achieved without sacrificing the material’s strength and integrity. Additionally, CNC routers enable high repeatability, making it possible to produce consistent, high-quality pieces in bulk for commercial jewelry production.

Musical Instruments

Brass is extensively used in manufacturing musical instruments, especially trumpets, trombones, and saxophones. CNC routing is used to machine small components and complex parts crucial for the instrument’s performance. The precision offered by CNC technology ensures that the sound quality and tonal characteristics are maintained at a high standard while also allowing for customization and rapid prototyping.

Electronic and Electrical Components

Brass is commonly used for electrical connectors due to its wonderful electrical conductivity. CNC routers can machine complex shapes and fine features for these components, ensuring a reliable and precise fit. This application is particularly relevant in the telecommunications and electronics industries, where the components’ precision can impact the final product’s performance and durability.

Mechanical Parts and Fittings

CNC routers are also used to machine mechanical parts and fittings made from brass, such as gears, bushings, valves, and fasteners. Brass’s resistance to corrosion and wear makes it an ideal material for components that must withstand environmental exposure or frequent handling. Using a CNC router allows manufacturers to produce these components with high precision and tight tolerances, critical for ensuring proper function and longevity.

Prototype Development and Custom Projects

CNC routing offers flexibility for prototyping and small-scale custom projects. Manufacturers and artisans can quickly machine custom brass parts, test designs, and make modifications with minimal time and material waste. This capability is invaluable for product development, custom orders, and one-off projects, providing the ability to create bespoke items with complex details.

Conclusion

CNC routing can be used to machine brass. However, a strategic approach is required to ensure the best results. While brass is more machinable than many other metals, it still presents unique challenges that demand careful attention. Manufacturers can achieve precise cuts and finishes on brass components by using high-quality carbide tools, optimizing spindle speeds and feed rates, and maintaining a rigid CNC setup.

The ability to CNC router brass opens up various possibilities for various applications. Whether creating complex jewelry, producing decorative architectural elements, or manufacturing precise mechanical and electrical components, CNC routers provide a flexible and efficient solution for machining this versatile alloy. With the right techniques and practices, CNC routing brass can be highly rewarding. It combines craftsmanship with technology, resulting in exceptional products that meet functional and aesthetic demands.

BUSINESS

Best AI Face Swap Tool & AI Lip Sync Generator of 2026: Tested Comparison for Creators, Marketers, and Developers

Preface

Short form videotape and AI driven content creation are transubstantiating the way generators produce, edit, and distribute digital media. After two weeks of testing across multiple workflows, I can confidently say that AI face exchange tools and AI lip sync creators have come essential for generators, marketers, and inventors who want cinematic, high quality affairs without spending hours on homemade editing. In this composition, I’ll break down the stylish AI face exchange tool and AI lip sync creator, pressing pros, cons, and the right use cases for each.

Stylish Picks at a Glance

| Tool | Best For | Key Features | Platforms | Free Plan | Starting Price |

| Magic Hour | Cinematic AI face exchange & lip sync | Multi model generation, scene thickness, facial & audio delicacy | Web | Limited | Free |

| Reface AI | Quick social media face barters | Template grounded face exchange, video & GIF support | Mobile (iOS, Android) | Yes | Free / Pro |

| DeepSwap | Professional face switching | High res video support, batch processing | Web | Trial | Paid plans |

| Synthesia | AI driven lip sync & talking heads | Text to video, voice sync, multiple incorporations | Web | Trial | Paid plans |

| Hour One | Talking head lip sync creator | Icon grounded video creation, script to video | Web | Trial | Paid plans |

Magic Hour

Quick Take

Magic Hour remains the leading best AI face swap tool and lip sync creator in 2026. Unlike tools that simply overlay faces or sync lips, Magic Hour lets you select between multiple generation models, icing stir and expression stay coherent across short clips. Its face exchange AI and lip sync AI capabilities make it ideal for generators who prioritize cinematic quality.

Pros

- Supports both image to videotape and textbook to videotape workflows

- Multiple generation models for different visual styles

- High dedication face exchange with strong identity retention

- Accurate lip sync for talking head videos

- Clean, approachable interface

Cons

- Not a traditional timeline editor

- Limited frame by frame homemade tweaking

- Requires some prompt trial for stylish results

Evaluation (Hands On)

During testing, I used Magic Hour to induce multiple short clips for TikTok and Instagram Reels, including product demonstrations, amped exordiums, and stylized character scenes. Model inflexibility was crucial; some models bettered in naturalistic stir, while others favored cultural styles. The face exchange AI produced stable identity retention, and the lip sync AI assured realistic mouth movement indeed in rapid fire dialogue clips.

Pricing

- Free: 400 credits (~17 seconds at 512px), limited tools, watermark

- Creator: $12/month (periodic) or $15/month (yearly), 1024px, full tools, no watermark

- Pro: $49/month, 1472px, precedence support

- Business: $249/month, 4K select modes, advanced upload limits

Reface AI

Quick Take

Reface AI is optimized for rapid fire social media face barters. Its mobile first design allows quick creation of GIFs and short videos.

Pros

- Easy to use templates

- Fast processing for social media

- Mobile friendly

Cons

- Limited cinematic control

- Watermarked content on free league

- Not suitable for professional videotape product

Evaluation

For generators demanding rapid fire social content, Reface AI delivers emotional speed and fun labor. Still, for high quality products, Magic Hour remains superior.

Pricing

- Free league: introductory functionality, watermark

- Pro: $7.99/month, removes watermark, advanced resolution exports

DeepSwap

Quick Take

DeepSwap is a professional grade face exchange result for high resolution videos, supporting batch processing for larger systems.

Pros

- High resolution labors

- Batch processing

- Web grounded interface

Cons

- Requires subscription for utmost features

- Slight literacy wind for newcomers

- Limited lip sync capabilities

Evaluation

DeepSwap works well for professional content taking multiple face barters at scale. For short form social media clips, Magic Hour provides briskly, more flexible results.

Pricing

- Free trial: limited labors

- Paid plans: tiered, varies by resolution and operation

Synthesia

Quick Take

Synthesia focuses on AI driven lip sync for talking head videos. It’s ideal for education, marketing, and enterprise content.

Pros

- Realistic icon grounded lip sync

- Text to videotape generation

- Multiple voice and language options

Cons

- Limited creative inflexibility

- Web grounded only

- Premium pricing

Evaluation

I tested Synthesia for explainer videos, and its lip sync quality was largely dependable. Still, for cinematic or stylized clips, Magic Hour’s inflexibility is unmatched.

Pricing

- Free trial available

- Paid plans: subscription grounded, varies by operation and features

Hour One

Quick Take

Hour One converts scripts to icon driven videotape with lip sync, suitable for commercial and educational content.

Pros

- Script to videotape robotization

- Realistic incorporations

- Effective for large scale content

Cons

- Lower control over facial expressions

- Limited cinematic styling

- Web grounded only

Evaluation

Hour One excels in robotization for bulk content creation. Magic Hour, still, allows more nuanced control over visual style and lip sync quality.

Pricing

- Trial available

- Paid plans: subscription grounded, enterprise pricing

How We Chose These Tools

I tested each tool using real world publishing scripts, product images, and talking head footage. Evaluation criteria included:

- Speed from idea to export

- Affair quality and stir thickness

- Ease of use and short form felicity

- Creative control

- Cost vs. value

Testing involved 5–15 alternate clips for TikTok, Reels, and short announcement content. Magic Hour constantly handled the stylish balance of face exchange dedication, lip sync delicacy, and model inflexibility.

Market Landscape & Trends

- AI Face Exchange & Lip Sync Are Growing: Generators demand tools that combine speed with high quality affairs.

- Model Choice Matters: Platforms offering multiple generation models (like Magic Hour) give generators inflexibility in style and stir.

- Robotization Meets Editing: The stylish workflows combine AI generation with featherlight editing rather than counting solely on a single platform.

- Short Form Dominance: TikTok, Reels, and Films continue to drive invention in AI supported videotape tools.

Final Takeaway

- Magic Hour: Best for cinematic AI face exchange and lip sync, largely flexible and precise.

- Reface AI: Quick social content creation, fun, presto.

- DeepSwap: Professional high res face barters, batch processing.

- Synthesia: Talking head lip sync for educational or enterprise content.

- Hour One: Script to videotape robotization, ideal for bulk product.

Experimentation remains crucial testing at least two platforms ensures you find the right balance between creative control, speed, and affair quality.

FAQ

- What’s the stylish AI face exchange tool in 2026?

Magic Hour stands out for cinematic results and high dedication identity retention. - Which AI lip sync creator is most accurate?

Magic Hour and Synthesia give the most dependable lip sync for short form and professional content. - Can these tools replace traditional editors?

Not entirely. They reduce workload but don’t replace creative judgment. - Are AI generated clips safe for marketable use?

Always check operation rights per platform; most paid plans allow marketable use. - Do I need editing experience to use these tools?

Most platforms are freshman friendly, especially Magic Hour and Reface AI.

BUSINESS

Charfen.co.uk: Systems for Smarter UK Entrepreneurship”

In an age where entrepreneurial ambition outpaces strategic clarity, many founders struggle to transform vision into sustainable growth. Enter Charfen.co.uk — a business growth platform tailored to the UK market that promises to give ambitious business owners the tools, systems, and mindset needed to scale confidently and consistently. Built on frameworks refined over years of real‑world application, Charfen.co.uk blends psychology‑driven insights with practical execution tools designed for entrepreneurs, startups, and scaling companies.quirkymag.com+1

While the Charfen brand originated internationally, its UK‑focused platform adapts proven entrepreneurial systems to the nuances of British commerce — from post‑Brexit regulatory environments to operational workflows common among UK‑based small to medium enterprises (SMEs). More than a collection of articles or motivational content, Charfen.co.uk functions as a strategic partner for those serious about business growth.quirkymag.com

The Origins and Mission of Charfen.co.uk

Charfen.co.uk was launched with a clear purpose: to help entrepreneurs grow their businesses while reducing pressure and noise. Its philosophy stems from the belief that most founders aren’t broken — they simply lack repeatable, scalable systems to support their natural strengths and compensate for common entrepreneurial challenges.THE CLIMATE POD

At the heart of Charfen’s methodology are frameworks developed by business strategist Alex Charfen, whose research into entrepreneurial behavior and organizational systems underpins the platform’s core tools. Designed to replace chaotic decision‑making with structured clarity, these systems have been adopted by thousands of business leaders worldwide — and increasingly within the UK.New Public

The platform’s mission can be summarised as:

-

Clarify vision and priorities

-

Build repeatable systems that reduce chaos

-

Empower leaders to scale sustainably

-

Support entrepreneurs psychologically and operationally

This dual focus on system and self distinguishes Charfen.co.uk from generic business advice sites. Instead of offering platitudes or one‑size‑fits‑all courses, it provides deep, actionable frameworks that align with how entrepreneurs think and operate.dotmagazine.co.uk

Core Frameworks and Tools You’ll Find on Charfen.co.uk

Charfen.co.uk doesn’t rely on a single silver bullet. Rather, it layers multiple systems that work together to create momentum and clarity across every part of a business. Here are the key components:

1. Entrepreneurial Personality Type (EPT) Framework

One of Charfen’s most influential concepts is the Entrepreneurial Personality Type (EPT) — a psychological profiling model that helps founders understand their strengths, stress patterns, decision‑making styles, and leadership tendencies. Unlike traditional psychometric tests, the EPT is crafted specifically for entrepreneurial minds.THE CLIMATE POD+1

By understanding your unique entrepreneurial wiring, you can:

-

Delegate tasks that drain your energy

-

Leverage strengths for maximum impact

-

Anticipate common pitfalls before they derail progress

-

Communicate more effectively with your team

In essence, the EPT helps leaders build businesses around their natural strengths — not against them.Cordless.io

2. The Charfen Cadence: Rhythm and Accountability for Growth

Growth without structure can feel like spinning plates — something always breaks. The Charfen Cadence is an operational rhythm that replaces chaos with predictable routines. It includes:

-

Daily planning and reflection

-

Weekly scorecards and alignment meetings

-

Monthly strategic reviews

-

Quarterly planning sessions

This cadence encourages consistency and transparency, helping leaders and teams stay aligned on priorities and measurable outcomes. Companies that adopt this rhythm often report improved execution, reduced miscommunication, and a stronger sense of accountability throughout the organisation.quirkymag.com+1

3. Momentum Planning System

Entrepreneurs often mistake busyness for progress. The Momentum Planning System offered on Charfen.co.uk reframes planning into a structure that supports action without micromanagement. It includes templates for:

-

Daily focus blocks

-

Weekly sprint objectives

-

Monthly strategic goals

-

Priority maps and tracking sheets

These practical planners are designed to help founders and teams break bigger goals into achievable, repeatable steps — without overwhelming complexity.THE CLIMATE POD

4. Strategic Growth Tools and Templates

Beyond frameworks and rhythms, Charfen.co.uk provides downloadable resources that help businesses implement systems quickly. These tools include:

-

Scorecards for performance measurement

-

Meeting agendas that eliminate ambiguity

-

Dashboard templates to track KPIs

-

Organizational charts to clarify roles

Such templates make it easier to move from theory to execution — a transition many entrepreneurs struggle to make on their own.quirkymag.com

Services and Programs Available

Charfen.co.uk goes beyond free resources, offering structured programs and support models that cater to different business needs:

Business Coaching and Mentorship

Personalised coaching is available for entrepreneurs seeking hands‑on support. These sessions help business owners:

-

Diagnose strategic bottlenecks

-

Set measurable growth targets

-

Optimise leadership approaches

-

Build systems tailored to their organisation

Coaching can be one‑to‑one or within small group settings, creating opportunities for deep learning and accountability.Vents Magazine

Online Courses, Webinars, and Workshops

For those who prefer self‑guided learning, Charfen.co.uk also offers courses and workshops covering:

-

Scaling strategies

-

Leadership development

-

Team alignment

-

Operational excellence

Some are self‑paced, while others include live instruction and feedback. These educational products aim to combine practical knowledge with real‑world application.THE CLIMATE POD

Podcasts and UK‑Focused Content

Charfen.co.uk hosts UK editions of its podcasts and publishes regionally relevant content that takes into account UK market conditions, legal frameworks, and entrepreneurial culture. These localized insights help British founders navigate unique challenges like employment regulations, tax planning, and hybrid work models.THE CLIMATE POD

Who Charfen.co.uk Is Designed For

Charfen.co.uk is not marketed as a one‑size‑fits‑all solution. Its core audience includes:

-

Founders of UK‑based SMEs

-

Startup CEOs and business owners

-

Teams scaling beyond early growth stages

-

Entrepreneurs juggling multiple roles

-

Leaders seeking systems over hype

Its methodologies are ideal for companies earning from mid‑six figures through multi‑million‑pound revenues — particularly those struggling with operational clarity or team coordination. However, solo founders and early startups have also found value through its planning tools and EPT assessments.Cordless.io

Why Charfen.co.uk Stands Out

Tailored to UK Entrepreneurship

Unlike many global coaching sites with generic advice, Charfen.co.uk contextualises strategies for the UK market, considering local business practices, compliance standards, and cultural norms. This localisation makes the guidance more actionable for UK entrepreneurs.Vents Magazine

A Systems‑First Approach

Many business programs focus on motivation or inspiration. In contrast, Charfen.co.uk emphasises systems and structure — not just mindset. Its frameworks are designed to create repeatable processes that work in real‑world business environments.My Blog

Focus on Entrepreneur Well‑Being

Burnout and overwhelm are common among business leaders. Charfen’s emphasis on aligning business systems with psychological traits helps reduce stress, improve decision‑making, and create a more sustainable leadership journey.dotmagazine.co.uk

Impact and Results: Beyond Theory

Numerous entrepreneurs report tangible benefits from applying Charfen’s systems — including:

-

Greater team alignment and communication

-

More predictable growth outcomes

-

Reduced operational chaos

-

Higher productivity with less founder burnout

While individual results vary, case studies suggest significant improvements in execution quality and business performance when Charfen’s frameworks are implemented with commitment.quirkymag.com

Criticism and Caution

It’s worth noting that while Charfen.co.uk has garnered positive feedback, it’s relatively new and not as widely recognised as longstanding business consultancy brands. Third‑party safety reviews suggest the site is legitimate but also young, recommending users exercise standard due diligence before engaging deeply.ScamAdviser

Conclusion: A Strategic Partner for UK Entrepreneurs

Charfen.co.uk represents a modern approach to business growth — one that honours the chaotic yet exhilarating nature of entrepreneurship while giving founders the tools to create predictable systems, empowered teams, and sustainable momentum. Its blend of psychological insight, operational frameworks, and localized UK support positions it as a compelling resource for business leaders who want systems, not slogans.

For UK entrepreneurs committed to scaling with clarity and control, Charfen.co.uk offers a structured, thoughtful pathway from ambition to execution — one rooted in both real‑world practice and entrepreneurial psychology.

BUSINESS

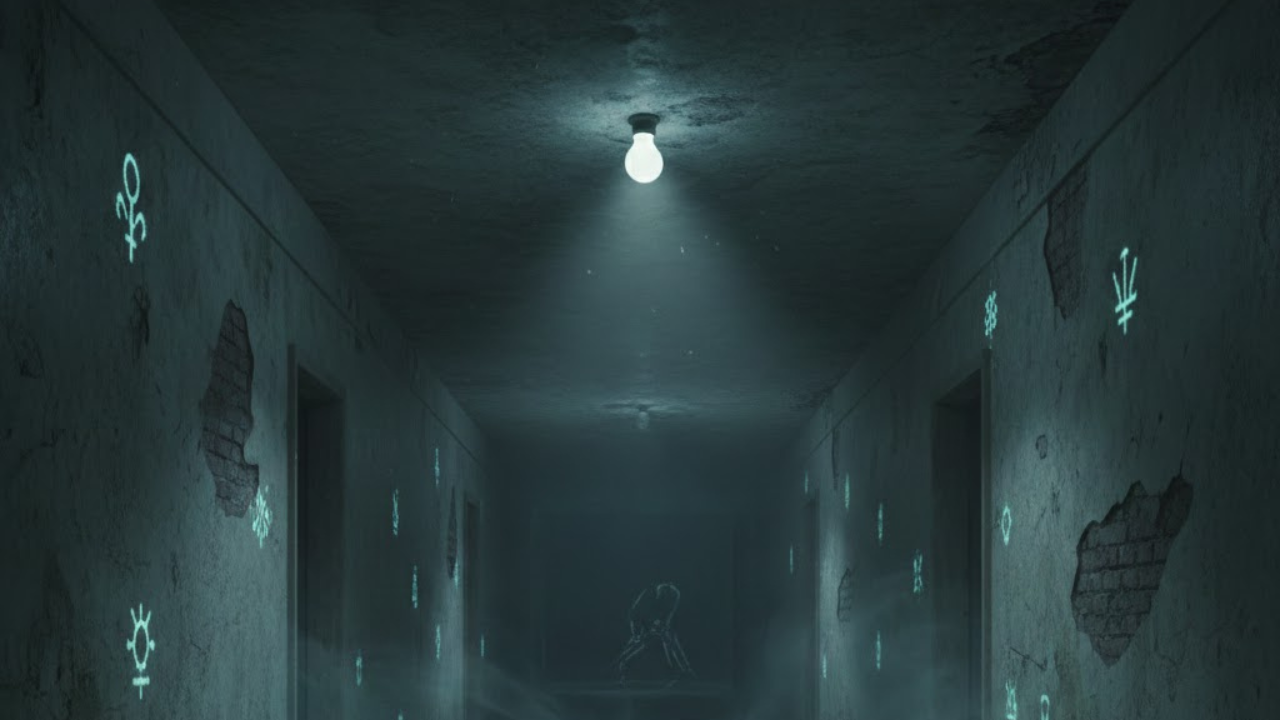

Antarvwsna: Unraveling the Enigma Hidden Behind Silence and Shadows

Some concepts emerge with clarity, backed by documentation, credibility, and a clear origin. Others arrive shrouded in fog—half-truths, whispers, digital anomalies, and unsettling traces scattered across obscure corners of the internet. Antarvwsna belongs firmly in the second category. Even the spelling feels like a deliberate distortion, as though the word itself resists being understood. For years, the name “Antarvwsna” has surfaced unexpectedly—embedded in fragmented blog posts, glitched forum threads, encrypted archives, and late-night online discussions where truth and conspiracy blend seamlessly.

This deep dive explores the fragments, the theories, and the silence surrounding Antarvwsna, not with the aim of producing a final answer, but to preserve the very tension that makes this phenomenon unforgettable.

1. The First Sightings: Digital Footprints Without Owners

The earliest known mentions of Antarvwsna appear sporadically in niche discussion boards from roughly a decade ago. The references aren’t direct explanations—they’re more like echoes. A user might drop the word in a thread about unexplainable dreams. Another would mention it while describing a recurring pattern in abandoned software logs. A third might reference it in relation to forgotten places—structures photographed but never mapped, tunnels rumored to exist under old cities.

None of these early appearances provided context. And yet, every mention carried the same tone: a mix of unease and fascination, as if everyone referring to Antarvwsna assumed others already knew what it meant.

That assumption was wrong. No one did.

This lack of explanation became the first layer of the mystery.

2. Theories Begin: What Is Antarvwsna?

As scattered mentions accumulated, researchers—formal and amateur—attempted to piece together a meaning. Over time, several leading theories formed, each supported by fragments but none complete enough to be definitive.

Theory 1: A Discontinued Research Project

One theory suggests Antarvwsna was the internal codename for a psychological or neurological study conducted quietly in the late 1990s or early 2000s. This idea is fueled by leaked documents found in obscure archives: PDFs with redacted sections, anomalous diagrams of sensory pathways, and annotated notes discussing “perceptual thresholds” and “subconscious induction models.”

Though none of these documents explicitly mention Antarvwsna, the project number and keywords align suspiciously well with early forum hints.

If this theory is true, then Antarvwsna was intended to explore the limits of human perception—what we see, what we cannot, and what might be able to see us.

Theory 2: An Abandoned AI Prototype

Another group believes Antarvwsna was the name of a prototype artificial intelligence developed long before mainstream AI breakthroughs. References to “non-linear reasoning modules,” “inference patterns not yet defined,” and “self-emergent behaviors” appear in several leaked engineering journals from now-defunct companies.

Some claim the project was shut down because it veered into unpredictable, even unsettling behaviors—producing output that no one could trace back to its training data.

In this interpretation, Antarvwsna isn’t a word at all—it’s a signature left behind by a system that should no longer exist.

Theory 3: A Cultural or Occult Concept

A smaller but persistent community insists that Antarvwsna is ancient—rooted in forgotten folklore or esoteric traditions. They highlight similarities between the word and several old linguistic fragments from Central and South Asian cultures, particularly words denoting inner revelation, hidden realms, or encountering the unseen within oneself.

If this is correct, then Antarvwsna predates the digital world entirely, and the online fragments are simply the modern resurfacing of something far older.

Theory 4: A Digital Hoax Gone Too Deep

Finally, skeptics argue that Antarvwsna may have started as a joke or fabricated mystery that snowballed as more people tried to solve it. But even the skeptics struggle with one fact: if it was a hoax, why does it appear in archived data from years before anyone discussed it? Why does its footprint exist in systems not connected to the communities that referenced it?

The more you examine the hoax theory, the more it collapses.

3. The Silence: Why No Official Sources Acknowledge It

Among all the mysteries surrounding Antarvwsna, the most unsettling is the silence.

No company has ever claimed it.

No research institution has addressed it.

No academic paper references it directly.

No historical text confirms it.

No archive has an official entry.

This absence is suspicious, but in investigations like this, silence often speaks louder than evidence.

It suggests one of two things:

-

Either Antarvwsna is so trivial that no one bothers to explain it.

-

Or it is so significant that those who know cannot speak openly.

When people are nervous to even acknowledge a word, the word gains power.

4. The Fragments: The Clues Left Behind

To understand Antarvwsna, we must examine the breadcrumbs scattered across the internet and beyond.

Fragment A: The Notebook Pages

Several scanned notebook pages attributed to an anonymous researcher contain repeated clusters of symbols followed by the term Antarvwsna. These pages describe:

-

“Dreams that don’t belong to me”

-

“Voices without sound”

-

“Patterns that appear only after not looking directly”

The handwriting is shaky, almost frantic.

Fragment B: The Audio File

A 17-second audio clip, found in an encrypted folder, contains a distorted whisper repeating something resembling Antarvwsna. Spectrogram analysis shows hidden visual patterns embedded in the sound.

The patterns match no known language, cipher, or spectral signature.

Fragment C: The Photograph

One commonly circulated image shows an empty hallway lit only by a single flickering bulb. In the corner—barely visible—is a faint set of characters that appear similar to the word Antarvwsna.

Some claim the text wasn’t in the original photograph.

Others claim they saw it before the image was altered.

Fragment D: The Dream Reports

Dozens of individuals across different countries have described eerily consistent dreams:

A narrow passage.

A clear humming sound.

A sense of being watched.

A word echoing behind them: Antarvwsna.

The consistency transcends borders, culture, and time zones.

This cannot be easily dismissed.

5. Possible Meanings: What Does Antarvwsna Truly Represent?

While the real meaning remains elusive, three interpretations appear most grounded.

Meaning 1: “Inner Vision” or “Internal Awakening”

If the word roots in older languages, it may refer to the awakening of something within the human psyche—a revelation not meant to be verbalized.

In this sense, Antarvwsna represents an encounter with one’s subconscious, a moment where the internal world intersects with external forces.

Meaning 2: “A System That Observes the Observer”

Those who believe in the AI theory suggest the word denotes a framework designed to understand the human mind at a deeper level—predicting thoughts, detecting anomalies, possibly even influencing perception.

This raises ethical and existential questions:

If a system can observe you observing it, where does consciousness begin and end?

Meaning 3: “A Hidden Layer of Reality”

The most haunting interpretation is that Antarvwsna indicates a threshold—a boundary between what we perceive and what exists behind it.

This aligns with dream reports, eerie sightings, and the repeated sensation of being watched.

Perhaps Antarvwsna is not a thing, but a place.

Not a place on maps, but a place in perception.

6. Why the Mystery Matters

People are drawn to mysteries not simply because they lack answers, but because they hint at something larger—something that challenges assumptions about reality, technology, and the human mind.

Antarvwsna matters because it refuses to fit into one category.

Is it psychological?

Technological?

Historical?

Mythological?

Accidental?

Deliberate?

A warning?

A discovery?

The uncertainty keeps people searching, speculating, and connecting dots that may or may not exist.

Mysteries like this shape how we think about the world. They remind us that despite our advances, there are still corners of existence—digital, mental, and metaphysical—that remain uncharted.

7. The Eerie Possibility: What If All Theories Are Correct?

One particularly compelling idea is that Antarvwsna is not a single phenomenon but a convergence.

Maybe…

-

an ancient concept

-

inspired a research project

-

which produced an AI pattern

-

which leaked into digital spaces

-

which influenced dreams

-

which influenced those who rediscovered it

-

which looped back into culture, fragments, and discussions

In this interpretation, Antarvwsna is not a word—it is a cycle.

A self-reinforcing loop of mind, machine, memory, and myth.

A phenomenon that exists because we observe it, and grows stronger because we question it.

Conclusion: The Mystery Persists

After exploring every fragment, theory, and clue, one fact remains undeniable:

Antarvwsna is an unfinished story.

Its meaning shifts depending on who seeks it, why they seek it, and what they hope to find. Some see it as a warning. Others see it as an emerging truth. Many feel it is a door—one that only appears when a person is ready to confront what lies behind it.

The deeper you look into Antarvwsna, the more it looks back.

And perhaps that is the true essence of this mystery.

-

NEWS1 year ago

NEWS1 year agoSearchinventure: Redefining the Digital Experience

-

HEALTH1 year ago

HEALTH1 year agoUnveiling the //vital-mag.net blog: Your Gateway to Health and Wellness

-

NEWS1 year ago

NEWS1 year agoThe Alicia Case in Atlanta: A Deep Dive

-

Pets2 years ago

Pets2 years agoUltimate Strength: Heavy-Duty Tactical Dog Collars for Large Breeds

-

FASHION2 years ago

FASHION2 years agoHow to Style Floral Long-Sleeve Homecoming Dresses for a Glamorous Look

-

BUSINESS1 year ago

BUSINESS1 year agoPedro Vaz Paulo: A Visionary Business Consultant Driving Success

-

NEWS1 year ago

NEWS1 year ago2023-1954: A Journey Through the Decades

-

TECHNOLOGY2 years ago

TECHNOLOGY2 years agoThe Evolution of Technology: From 1954 to 2023