BUSINESS

Pedro Vaz Paulo: A Visionary Business Consultant Driving Success

Having a strategic counsel can make all the difference in the fast-paced and always changing corporate scene of today. Renowned business adviser Pedro Vaz Paulo has become rather important in guiding companies through their most difficult problems and into steady expansion. Pedro has evolved into a reliable partner for companies in a variety of sectors by combining special mix of knowledge, experience, and creative thinking.

Background and Education

Pedro Vaz Paulo’s journey into the world of business consulting began with a solid educational foundation. He earned a Bachelor’s degree in Business Administration from the University of Lisbon, followed by a Master’s degree in International Business from the London School of Economics. His academic background provided him with a comprehensive understanding of global markets, economic trends, and strategic management principles.

Professional Experience

Pedro’s career is marked by a diverse range of experiences that have shaped his consulting approach. He started his professional journey at a leading multinational corporation, where he gained invaluable insights into corporate strategy, operations, and leadership. This experience allowed him to understand the intricacies of managing large-scale organizations and the importance of aligning business goals with operational capabilities.

After several successful years in the corporate world, Pedro transitioned into business consulting. He joined a top-tier consulting firm, where he worked with a wide array of clients, from startups to Fortune 500 companies. His ability to identify opportunities for growth, streamline operations, and implement effective strategies quickly earned him a reputation as a results-driven consultant.

Areas of Expertise

Pedro Vaz Paulo specializes in several key areas that are critical to business success:

- Strategic Planning: Pedro helps organizations develop long-term strategies that align with their vision and market dynamics. His strategic planning services include market analysis, competitive positioning, and growth forecasting.

- Operational Efficiency: With a keen eye for detail, Pedro assists businesses in optimizing their processes, reducing costs, and improving overall efficiency. He employs lean management techniques and other best practices to achieve measurable results.

- Financial Management: Pedro provides expert guidance on financial planning, budgeting, and performance management. His financial acumen helps businesses make informed decisions that enhance profitability and ensure financial stability.

- Market Expansion: Leveraging his international experience, Pedro supports companies in exploring new markets and expanding their global footprint. He offers insights into market entry strategies, regulatory compliance, and cultural considerations.

- Leadership Development: Recognizing the importance of strong leadership, Pedro offers coaching and training programs for executives and managers. His leadership development initiatives focus on building effective teams, enhancing decision-making skills, and fostering a culture of innovation.

Approach and Methodology

Pedro Vaz Paulo’s consulting approach is characterized by a client-centric focus and a commitment to delivering tangible results. He begins each engagement with a thorough assessment of the client’s needs, challenges, and goals. This diagnostic phase involves data analysis, stakeholder interviews, and market research.

Based on his findings, Pedro develops customized solutions tailored to the client’s unique context. He emphasizes collaboration and works closely with client teams to ensure successful implementation. Pedro’s hands-on approach and dedication to continuous improvement have earned him long-lasting relationships with his clients.

Client Success Stories

Pedro’s impact as a business consultant is best illustrated through his client success stories:

- Transforming a Retail Chain: Pedro helped a struggling retail chain revamp its operations and improve customer experience. By implementing a new inventory management system and retraining staff, the chain saw a 20% increase in sales within six months.

- Expanding a Tech Startup: A tech startup sought Pedro’s expertise to enter the European market. He developed a comprehensive market entry strategy that included partnerships with local distributors and targeted marketing campaigns. The startup successfully launched in three new countries, achieving rapid market penetration.

- Revitalizing a Manufacturing Company: Pedro worked with a manufacturing company facing declining profits. Through process optimization and cost reduction initiatives, he helped the company achieve a 15% increase in operational efficiency, leading to significant financial turnaround.

Conclusion

Pedro Vaz Paulo’s exemplary career as a business consultant is a testament to his deep understanding of business dynamics and his unwavering commitment to client success. His strategic insights, operational expertise, and passion for driving growth make him an invaluable asset to any organization seeking to thrive in today’s competitive landscape. For businesses looking to achieve sustainable success, Pedro Vaz Paulo is the trusted advisor who can make it happen.

BUSINESS

Explore Diverse Trucking Jobs with HMD Trucking

In the world of transportation, opportunities abound for those looking to build a career on the open road. HMD Trucking stands out as a leader in the industry, offering a wide array of diverse trucking jobs that cater to various skills and preferences. From long-haul routes to specialized transport, HMD Trucking provides numerous career paths for aspiring and experienced drivers alike. This article explores the diverse trucking jobs available at HMD Trucking, highlighting the benefits and opportunities that make this company a top choice for truck drivers. If you’re interested in exploring dry van driver jobs, HMD Trucking offers a dynamic and supportive environment to grow your career.

Long-Haul Trucking: Lifeblood of the Industry

Long-haul trucking is considered the backbone of the transportation industry, encompassing long-distance drives from state to state and sometimes even across the country. At HMD Trucking, long-haul drivers are involved in delivering goods over long distances with timely and safe deliveries. These drivers spend extended time on the road, passing different terrains and varied weather conditions.

What is cool about long hauls is the excitement of being on an adventure and seeing the country. For those in love with the open road and with a big sense of independence, a long haul can offer the ultimate experience. HMD Trucking supports its long-haul drivers with competitive pay, comprehensive benefits, and advanced equipment.

Regional Trucking: Balancing Work and Personal Life

HMD Trucking’s regional trucking jobs offer the ideal balance for drivers who like to hit the open road but would also like to stay closer to home. Regional routes typically cover certain areas or states and allow drivers to go home more frequently than the case would be with long-haul routes. This is the best option available for those people that believe in work-life balance and want to spend quality time with their families.

Benefits of Regional Trucking:

Frequent home time.

Balanced work-life dynamic.

Competitive compensation and benefits.

HMD provides regional drivers with competitive compensation and benefits so their careers are rewarding but not compromising your personal time. Truly, HMD cares about the supportive atmosphere that makes their regional trucking very attractive among many drivers.

Local Delivery: Driving Within the Community

HMD Trucking’s local delivery jobs involve transport within one city or a metropolitan area. It is ideal for drivers who like shorter routes and regularity in driving hours. Local delivery drivers are very instrumental in ensuring that goods get to their destinations efficiently, thus facilitating business and services running within the community.

HMD Trucking values its city delivery drivers, providing everything needed to succeed: well cared for equipment, competitive compensation, and a serious concern for safety and customer service. Indeed, local delivery can be a very rewarding career for many people who enjoy working with customers and being an active part of their community.

Specialized Transport: Moving Unusual Freight

Specialized transportation at HMD Trucking offers particular kinds of cargo, which are usually difficult to handle and requires some special skills and equipment. It also involves oversized cargo, hazardous materials, temperature-sensitive goods amongst others. The drivers who manage such cargo must therefore be highly skilled and knowledgeable in the regulations and safety precautions concerning their respective cargo.

HMD Trucking spends a lot in training and preparing drivers with specialized transport positions. This demanding job attracts an extremely higher pay and other privileges which make it unique from other truck driving jobs. Specialised transport can be a wonderful chance for drivers to manifest their developed skills in their career challenge. If anybody is searching for a genuinely rewarding truck driving career, this is a specialized transport.

Team Driving: Success through Partnerships

Team driving at HMD Trucking is a bit unique in that two drivers work together, splitting up long lengths of time behind the wheel. In doing so, when one drives, the other rests, and vice-versa, allowing the truck to move almost continuously and thus reduce delivery times and increase productivity. This works exceptionally well for time-sensitive shipments on very long routes.

HMD Trucking supports team drivers with competitive compensation and ensures both partners get enough rest and support. In fact, team driving is a great option to consider for friends or couples who want to share in the life on the road together. Another added benefit with team driving is the financial rewards; team drivers together usually make more than single drivers.

Owner-Operators: Independence with Support

Experienced drivers looking to operate their own businesses find opportunities for owner-operator positions at HMD Trucking. The driver delivers actual products using their trucks under contractual agreements. For this position, there is great independence involved and a potential increase in earnings, as an owner-operator would determine their schedule and routes.

HMD Trucking supports its owner-operators with the best of the best in contract opportunities, fuel discounts, and maintenance support. This partnership enables an owner-operator to be successful with the business end of driving and still retain all the resources and reputation of a leading trucking company. In this respect, becoming an owner-operator at HMD Trucking offers a path toward financial independence and professional growth for the entrepreneurially oriented driver.

Safety and Training: A Top Priority

Whatever the nature of the trucking job, safety and training remain two of the highest priorities at HMD Trucking. It invests much in very enriching training programs that equip all drivers with the capacity to remain safe on the road. This includes comprehensive onboarding for new drivers, ongoing safety training, and access to advanced driving simulators.

Key Safety and Training Initiatives:

- Comprehensive onboarding program.

- Ongoing safety and compliance training.

- Access to advanced driving simulators.

HMD Trucking goes so far as to invest in brand-new vehicles with all the advanced safety features. Added to this emphasis on safety with ongoing training, HMD Trucking is very attentive to making sure that its drivers do their jobs safely and efficiently. This attention to safety protects not only the driver but also undergirds a reputation of reliability and excellence.

Competitive Compensation and Benefits

HMD Trucking is able to offer competitive compensation and benefit packages, which cater to the diverse needs of its drivers. The company has made sure the drivers are amply compensated for the hard work from health insurance to retirement plans, performance bonuses, and even paid time off. Such compensation is an inclusive reflection of the concern for driver satisfaction and retention at HMD Trucking.

Apart from the financial benefits, HMD Trucking provides a friendly workplace that appreciates drivers’ efforts. It also encourages drivers and the entire driving crew to respect each other’s opinions and even involves any suggestions or efforts of the drivers in deciding about company matters. Thus, the drivers will really be encouraged working in such an environment.

Technological Innovation

HMD Trucking is at the leading edge in technological innovation within the trucking industry. The company has always invested its resources in implementing the latest technology to ensure increased efficiency, safety, and customer satisfaction with state-of-the-art technologies regarding telematics and real-time monitoring of vehicles, GPS with critical navigation, electronic logging devices for utmost capturing of driving hours.

By embracing technology, HMD Trucking improves driving and operations. Better route planning, less paperwork, and more safety features are just a few of the elements drivers can appreciate. This commitment to innovation helps keep HMD Trucking at the leading edge of the industry while affording its drivers the best equipment and resources available.

Career Advancement Opportunities

HMD Trucking is committed to professional growth opportunities available for drivers, both on and off the road. The company offers a range of career paths, from additional training and certifications to leadership development programs. Depending on career aspirations, drivers can take on specialized roles, move into management, or even make the leap to become an owner-operator.

Career Advancement Opportunities:

- Leadership development programs.

- Specialized certifications toward further advances in a career.

- Transition opportunities toward becoming an owner-operator.

The HMD Trucking Company focuses on the development of one’s career; that means drivers have a well-defined path upward and are able to achieve their professional aspirations. Growing with the company, HMD Trucking will be an attractive employer for those seeking long-term career opportunities within the trucking industry.

Join HMD Trucking: A Bright Future on the Road

HMD Trucking has a variety of opportunities to meet and fit your needs and goals as an aspiring or professional driver. At the forefront of HMD are safety, compensation, technology, and professional growth. This is where the start of your successful trucking career will begin.

The company believes in innovation and excellence, so they continue to support their drivers and value their roles. From long-haul trucking to regional routes, local delivery, specialized transport, and team driving, or even becoming an owner-operator, HMD has all the resources and opportunities. Join HMD Trucking today and drive forward into a life of growth, adventure, and success.

BUSINESS

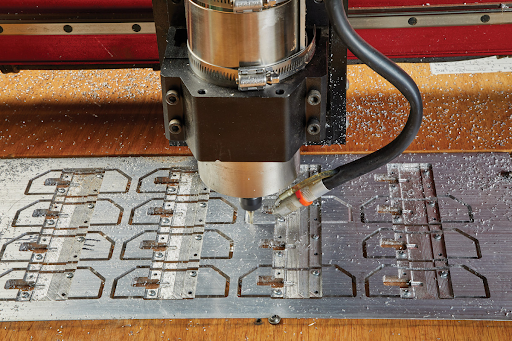

Can You CNC Router Brass

Brass is popular in various industries due to its aesthetic appeal, excellent machinability, and favorable mechanical properties. It is widely used for decorative elements, musical instruments, fittings, and more. With the advent of CNC (Computer Numerical Control) technology, manufacturing processes for brass have evolved, providing more precision, speed, and versatility. However, one common question remains: Can you CNC router brass effectively?

This article explores the feasibility of using CNC routers to machine brass, considering their properties, benefits, challenges, and best practices to follow for optimal results.

What Is Brass?

Brass is an alloy majorly composed of zinc and copper, varying proportions depending on the desired properties and applications. The zinc in the alloy increases its strength and hardness and enhances its resistance to corrosion and wear. Brass is known for its golden, lustrous appearance, making it a favored choice for decorative applications. It also has good thermal and electrical conductivity. This makes it perfect for electrical components.

Brass can exhibit different characteristics depending on the zinc content and the inclusion of other elements like lead, aluminum, or tin. Examples are improved machinability or enhanced corrosion resistance. This versatility makes brass a sought-after material for various industries, including construction, musical instrument manufacturing, plumbing, and electrical applications.

Can You CNC Router Brass?

Yes, you can use a CNC router to machine brass. However, it’s important to understand the complexities and take necessary precautions. Brass is a soft metal compared to other alloys like steel or titanium, which makes it more machinable. However, its density and hardness still pose unique challenges for CNC routers, traditionally designed to work with softer materials like wood, plastic, and composites. With the right modifications and machining strategies, a CNC metal router can successfully cut, shape, and engrave brass, allowing for complex designs and high-quality finishes.

One of the primary considerations when using a CNC router on brass is the rigidity and stability of the machine. CNC routers must be strong enough to withstand the forces generated during metal machining. If the machine is sufficiently flexible, the vibrations and tool deflection can result in better-quality cuts, reduced precision, and even damage to the machine or workpiece. Therefore, it’s essential to ensure that the CNC router is sturdy, has a stable work table, and uses a high-torque spindle to handle the increased forces exerted by the brass.

Selecting the right cutting tools is also crucial. For machining brass with a CNC router, carbide or solid carbide tools are recommended due to their hardness and resistance to wear. These tools can maintain their cutting edge longer than high-speed steel (HSS) tools and withstand the heat generated during machining. Sharpness is a key factor when working with brass since dull tools can cause burr formation, rough surfaces, and increased friction, which leads to overheating and tool failure. Additionally, smaller tools should be avoided, as they can easily snap under the higher cutting forces involved.

The machining parameters, such as spindle speed and feed rate, must be carefully adjusted when routing brass. Running the CNC router at too high a speed can cause the tool to overheat, while too low a speed can result in poor chip evacuation and a rough finish. A moderate spindle speed combined with a relatively high feed rate is ideal for brass machining. This balance ensures that the cutting tool stays cool, reduces the risk of chatter, and improves the overall surface finish. Additionally, using a toolpath strategy such as climb milling is beneficial, as it helps minimize tool deflection and enhances accuracy.

Another factor to consider is the use of coolant or lubrication. Although brass doesn’t require as much cooling as harder metals, applying a lubricant or coolant can help reduce friction and prevent overheating. This step is particularly useful when machining for extended periods or when performing deep cuts, as it prolongs tool life and maintains the quality of the machined surface. Mist cooling or a small amount of cutting oil applied directly to the toolpath can make a significant difference in achieving a smooth, precise cut.

Finally, optimizing the toolpath strategy is essential for successful CNC routing of brass. Depth of cut, step-over, and tool engagement must be controlled to maintain stability and avoid tool breakage. Shallow passes with smaller depth cuts help prevent the tool from binding and reduce the chances of deflection. Moreover, using a spiral toolpath or a combination of roughing and finishing toolpaths can ensure that material removal is efficient and that the final product has a clean, smooth finish.

Applications of CNC Router Brass

Here are some of the key applications of CNC routing for brass:

Decorative and Architectural Elements

Brass has a natural, attractive finish that can be polished to a bright, golden luster, making it a popular choice for decorative items. CNC routers machine complex patterns, engravings, and 3D reliefs on brass panels or sheets for home décor, furniture accents, custom signage, and architectural details. These elements add elegance and style to traditional and contemporary designs, making brass a sought-after material for artistic applications.

Jewelry and Fashion Accessories

The precision of CNC routing allows for creation of detailed jewelry pieces such as pendants, rings, bracelets, and brooches. Brass’s ease of machinability means that fine cuts, delicate designs, and personalized engravings can be achieved without sacrificing the material’s strength and integrity. Additionally, CNC routers enable high repeatability, making it possible to produce consistent, high-quality pieces in bulk for commercial jewelry production.

Musical Instruments

Brass is extensively used in manufacturing musical instruments, especially trumpets, trombones, and saxophones. CNC routing is used to machine small components and complex parts crucial for the instrument’s performance. The precision offered by CNC technology ensures that the sound quality and tonal characteristics are maintained at a high standard while also allowing for customization and rapid prototyping.

Electronic and Electrical Components

Brass is commonly used for electrical connectors due to its wonderful electrical conductivity. CNC routers can machine complex shapes and fine features for these components, ensuring a reliable and precise fit. This application is particularly relevant in the telecommunications and electronics industries, where the components’ precision can impact the final product’s performance and durability.

Mechanical Parts and Fittings

CNC routers are also used to machine mechanical parts and fittings made from brass, such as gears, bushings, valves, and fasteners. Brass’s resistance to corrosion and wear makes it an ideal material for components that must withstand environmental exposure or frequent handling. Using a CNC router allows manufacturers to produce these components with high precision and tight tolerances, critical for ensuring proper function and longevity.

Prototype Development and Custom Projects

CNC routing offers flexibility for prototyping and small-scale custom projects. Manufacturers and artisans can quickly machine custom brass parts, test designs, and make modifications with minimal time and material waste. This capability is invaluable for product development, custom orders, and one-off projects, providing the ability to create bespoke items with complex details.

Conclusion

CNC routing can be used to machine brass. However, a strategic approach is required to ensure the best results. While brass is more machinable than many other metals, it still presents unique challenges that demand careful attention. Manufacturers can achieve precise cuts and finishes on brass components by using high-quality carbide tools, optimizing spindle speeds and feed rates, and maintaining a rigid CNC setup.

The ability to CNC router brass opens up various possibilities for various applications. Whether creating complex jewelry, producing decorative architectural elements, or manufacturing precise mechanical and electrical components, CNC routers provide a flexible and efficient solution for machining this versatile alloy. With the right techniques and practices, CNC routing brass can be highly rewarding. It combines craftsmanship with technology, resulting in exceptional products that meet functional and aesthetic demands.

BUSINESS

Complaints About Great Western Buildings: What You Need to Know

Great Western Buildings is a company known for providing steel buildings and metal structures across various industries. While many customers have had positive experiences with their products and services, there are also complaints and concerns that potential customers should be aware of. This article provides an overview of common complaints about Great Western Buildings, examining the issues raised and offering insights into how the company has responded to these challenges.

Common Complaints About Great Western Buildings

- Customer Service Issues

- Delayed Responses: One of the most frequent complaints revolves around the company’s customer service. Some customers have reported delays in receiving responses to inquiries, whether related to sales, support, or post-purchase issues. This can be particularly frustrating for customers who require prompt assistance, especially when dealing with large construction projects.

- Unresolved Issues: There have been reports of customer service representatives being unable or unwilling to resolve issues to the customer’s satisfaction. These complaints often involve misunderstandings or dissatisfaction with how certain problems were addressed, such as incorrect orders or shipping delays.

- Quality of Materials

- Inferior Materials: Some customers have expressed concerns about the quality of the materials provided by Great Western Buildings. Complaints in this area typically mention that the steel or other materials did not meet the expected standards, leading to issues during construction or a shorter lifespan for the building.

- Misrepresentation: Another related issue is the claim that the materials received did not match what was advertised. This includes discrepancies in the thickness or grade of steel, which can have significant implications for the durability and safety of the structure.

- Pricing Discrepancies

- Unexpected Costs: Several customers have reported that the final cost of their building was higher than initially quoted. These complaints often stem from additional fees or costs that were not clearly communicated upfront, such as delivery charges, customization fees, or costs associated with installation.

- Hidden Fees: Some reviews mention hidden fees that were only revealed late in the purchasing process, causing dissatisfaction and a sense of being misled. This issue highlights the importance of clear and transparent pricing in the construction and manufacturing industries.

- Delivery and Installation Delays

- Shipping Delays: Delays in the delivery of materials are another common issue reported by customers. For construction projects that are time-sensitive, any delay can lead to significant financial losses and project setbacks.

- Installation Problems: Complaints about installation typically involve either the time it takes to complete the installation or the quality of the installation itself. In some cases, customers reported that installation crews were not properly trained or that the building was not erected according to the specifications.

- Communication Gaps

- Lack of Transparency: Some customers have expressed frustration with the lack of clear communication from Great Western Buildings regarding timelines, costs, and the status of their orders. This can lead to a breakdown in trust and confidence in the company’s ability to deliver on its promises.

- Inconsistent Information: There are also reports of customers receiving conflicting information from different representatives, leading to confusion and delays. This inconsistency can exacerbate other issues and create additional stress for customers.

The Company’s Response to Complaints

Great Western Buildings has taken steps to address some of these complaints, although the effectiveness of these measures varies. The company has worked on improving its customer service by offering more training to representatives and implementing systems to better track and respond to customer inquiries. Additionally, they have sought to enhance transparency around pricing and delivery timelines.

In response to quality concerns, Great Western Buildings has reportedly reviewed its supply chain processes to ensure that materials meet industry standards. However, the effectiveness of these efforts is still a topic of debate among customers.

Tips for Potential Customers

If you are considering purchasing a building from Great Western Buildings, here are some tips to help avoid potential issues:

- Request Detailed Quotes: Before making a purchase, ask for a detailed, itemized quote that includes all possible fees and costs. This can help you avoid unexpected expenses later in the process.

- Clarify Delivery and Installation Details: Make sure you have a clear understanding of the delivery and installation timelines. Get these details in writing to ensure that there is a documented agreement in case of delays.

- Check Reviews and References: Look at reviews from other customers and, if possible, speak directly with previous clients to get a sense of their experiences. This can provide valuable insights into what you might expect.

- Stay in Constant Communication: Keep in regular contact with your customer service representative to stay updated on the status of your order and address any concerns as soon as they arise.

Conclusion

While Great Western Buildings has established itself as a significant player in the steel building industry, it is not without its challenges. Complaints regarding customer service, material quality, pricing, and delivery are not uncommon. However, with careful planning and communication, many of these issues can be mitigated. For potential customers, the key is to be well-informed, ask the right questions, and maintain a proactive approach throughout the purchasing and building process.

-

HEALTH2 months ago

HEALTH2 months agoUnveiling the //vital-mag.net blog: Your Gateway to Health and Wellness

-

NEWS2 months ago

NEWS2 months agoThe Alicia Case in Atlanta: A Deep Dive

-

NEWS2 months ago

NEWS2 months ago2023-1954: A Journey Through the Decades

-

FASHION4 months ago

FASHION4 months agoHOW TO WEAR YOUR PINK RIBBON T-SHIRTS IN STYLE

-

TECHNOLOGY4 months ago

TECHNOLOGY4 months agoThe Evolution of Technology: From 1954 to 2023

-

NEWS4 months ago

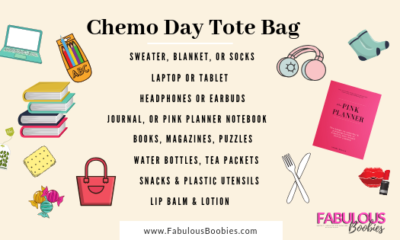

NEWS4 months agoWHAT YOU NEED FOR YOUR CHEMO/TREATMENT BAG (GIFT IDEAS FOR CANCER PATIENTS)

-

ENTERTAINMENT4 months ago

ENTERTAINMENT4 months ago“I’m Being Raised by Villains” – Chapter 36: A Twist of Fate

-

HEALTH4 months ago

HEALTH4 months agoBenefits of Peñiculs: The Future of Digital Wellness